Why even decide to produce plastic materials? Firstly, plastic production usually has the benefit of having fairly fast completion times, and in contrast to the majority of materials there’s also the option of colouring plastic before manufacturing, as opposed to after. It’s high malleability means that it possesses a relatively low melting temperature, and it is far more lightweight compared to many other materials – these two factors simplify the production operation. Moreover, plastics are relatively inert and thus possess higher chemical resistance. Irrespective of all of these positive aspects, plastic material is however not suitable for purposes which require a very high physical integrity, and is really at risk from wear and tear in the long-term.

Summary Of CNC Machining

CNC machining is a computer governed subtractive approach, that eliminates material from plastic in order to build the desirable form. The computer is high-tech, with the ability to transform a design into figures using a computer aided design computer software system. The figures are competent to control the machine to cut the desired form. To set up, the pieces of equipment require an intermediate stage in the development and validation of tool paths. Once the machine obtains the tool paths, the subtractive process is initiated. When the assembly is finished, the component is washed, smoothed, and cut.

For low volume plastic component part applications that need tight tolerances and forms which are challenging to mould, machining meets your needs. CNC machining has the benefit of minimal to medium initial expenses, and can turn out top quality plastic parts with minimal completion times. On the other hand, with an increase of product complexity, the price per part climbs up. Additionally, this process demands tool access considerations, and certain shapes, including those with spherical inner channels, are near-impossible to form using CNC manufacturing.

Overview Of Vacuum Formation

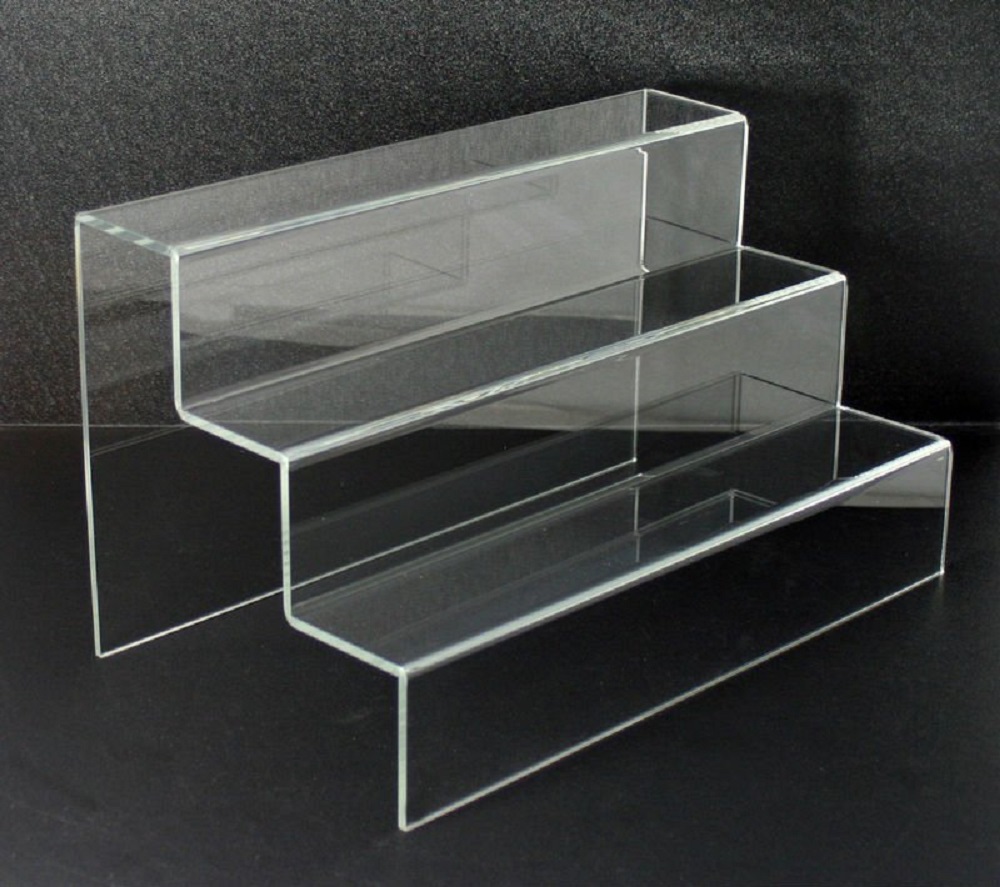

Vacuum formation is a method in which plastic material is heated and moulded, typically using a mould. The size and sophistication of vacuum-forming machines cover anything from affordable desktop devices to innovative manufacturing machinery.

It is usually suited to any project, ranging from custom designs to large-scale production, considering the large variety of equipment offered and that also automation is undoubtedly an option when necessary. Even so, there’s little flexibility in the different kinds of design it can develop, and is also unfortunately exclusively competent to build components with simple geometries. In comparison to other methods, tooling prices are low, given that vacuum formation only needs minimal forces and pressures. Generally, for modest production sizes the moulds are constructed with 3D printed resin, or possibly plaster, and then for larger development sizes more robust equipment composed of metal is used.

The manufacturing method begins with a sheet of plastic getting clamped and heated up up until the plastic becomes mouldable. The plastic will then be put into the mould and chilled, and often fans and also other cooling strategies are implemented in an effort to speed up the cooling process. The ultimate stage entails any surplus plastic being removed. {There are so many acrylic forming online sites throughout the Uk, if you are looking for more information or sometimes asking prices this blog is a good kick off point acrylic extrusion manufacturer. There are a number perspex suppliers Uk internet resources in great Britain, if you’re looking for additional information or alternatively bargains this page is a superb place to begin www.displaydevelopments.co.uk/bespoke-manufacturing/perspex-fabrication-ib-156.html. In case you’re looking at further information with reference to machining acrylic plastic this specific web site plastic parts development provides a whole lot more information articles connected with plastic heat moulding.